Thermostat-controlled gage

Overview

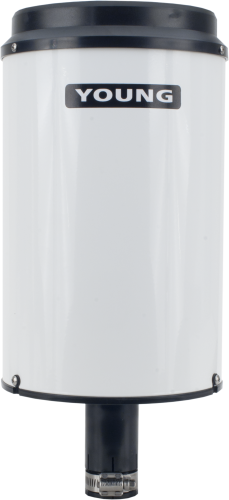

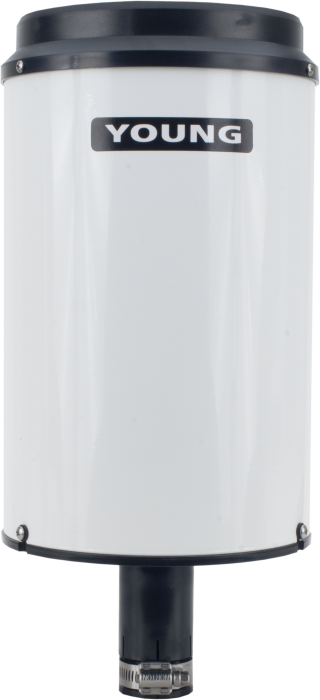

The 52202, manufactured by R. M. Young, is a thermostat-controlled, electrically heated, tipping bucket rain gage. You can use it to measure rain, snow, and other frozen precipitation. Its catchment area of 200 cm2 and measurement resolution of 0.1 mm meet the recommendations of the WMO. This heated rain gage is compatible with most Campbell Scientific dataloggers, and it is used in environmental monitoring applications.

Read MoreBenefits and Features

- High precision—tips at 0.1-mm increments

- Heating element melts snow and ice for year-round measurements

- Compatible with many Campbell Scientific data loggers

Images

Related Products

Technical Description

The 52202 funnels precipitation into a bucket mechanism that tips when filled to the calibrated level. Each tip is marked by a magnetic reed switch closure that is recorded by a Campbell Scientific datalogger pulse count channel.

The 52202 has a thermostat-controlled internal heater that melts snow or other frozen precipitation. This heater requires a reliable source of 24 Vac power. A wall transformer is shipped with the 52202 that plugs into a wall socket to provide the required 24 Vac power.

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Dataloggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR300 (retired) | ||

| CR3000 (retired) | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR800 (retired) | ||

| CR850 (retired) | ||

| CR850 (retired) | ||

| CR850 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

Mounting

The 52202 is shipped with a mounting pipe. The rain gage clamps onto this pipe, which is then fastened to a crossarm using the CM220 Right-Angle Mounting Kit, or mounted onto the top of a tripod using the CM216 Sensor Mounting Kit.

Wind Screen

Campbell Scientific offers the 260-953 Wind Screen to help minimize the affect of wind on the rain measurements. This wind screen consists of 32 leaves that hang freely and swing as the wind moves past them.

Specifications

| Sensor Type | Tipping bucket with magnetic reed switch (normally open) |

| Measurement Uncertainty |

|

| Rainfall per Tip | 0.1 mm (0.004 in.) |

| Operating Temperature Range | -20° to +50°C (heated) |

| Humidity Range | 0 to 100% |

| Power | 18 W @ 24 Vac (for heater only) |

| Heater Thermostat Set Point | 10°C ±3°C |

| Contact Rating | 24 Vac/dc (400 mA maximum) |

| Compliance with Standards |

|

| Mounting Pipe | 30.5 cm (12 in.) length; 1 inch IPS, aluminum, unthreaded |

| Catchment Area | 200 cm2 (31 in.2) |

| Orifice Diameter | 16 cm (6.3 in.) |

| Diameter | 18.5 cm (7.3 in.) |

| Height | 30 cm (11.8 in.) |

| Power Plug Weight | 0.43 kg (0.95 lb) |

| Weight | 1.16 kg (2.55 lb) |

Related Documents

Related FAQs

Number of FAQs related to 52202-L: 10

Expand AllCollapse All

-

These rain gages can be connected to either.

- When a control port is used, one lead goes to the 5 V port to provide current, and the other lead goes to a control port to detect the current.

- When a pulse channel is used, one lead goes to the pulse port, and the other lead terminates on a ground terminal.

-

Follow the steps listed in the “Troubleshooting” section of the 52202-L Instruction Manual.

-

The 52202-L uses a reed switch to generate a pulse for each tip of the collector.

-

No. The relay that controls power to the heater uses ac power only.

-

Not enough tips or too many tips.

-

Not registering any tips, missing tips, or double tips.

-

When a rain gage is out of calibration, it is usually because of the buildup of dirt and grime on the internal surfaces of the tipping bucket mechanism. Cleaning the internal surfaces usually brings the rain gage back into calibration. It is also possible that a rain gage is out of calibration because it is no longer level.

To minimize the possible occurrence of calibration errors, perform routine cleaning and maintenance of the rain gage at least once every three months. The environmental conditions at a particular site may require a facility to perform cleaning, leveling, and maintenance on a much more frequent schedule.

-

The most common errors are either that the rain gage appears to have drifted out of calibration or that the tips are not being correctly recorded by the datalogger.

-

If data is not being logged correctly, there are two likely causes:

- The reed switch has failed.

- There is a faulty connection from the rain gage to the datalogger, typically caused by a broken conductor or corroded wiring.

-

The 260-953 Alter-type rain gage wind screen consists of 32 heavy metal leaves that hang freely and swing as the wind moves past them. The swinging leaves act as a wind damper and help minimize the effect of wind on the rain measurements without adding additional turbulence.

Case Studies

Overview In a landmark milestone for global meteorological cooperation, Rwanda has become the first country to......read more

This case study discusses the integration of CPEC310 and AP200 systems to explore the theories......read more