Product Line

Retired Products

Related Documents

Related FAQs

Number of FAQs related to Data Loggers & Data Acquisition Systems: 18

Expand AllCollapse All

-

Yes, but there is the potential for explosive hydrogen gas from a rechargeable battery to build up inside the airtight, waterproof enclosure. Care should be exercised in choosing a power supply for applications where the enclosure must be waterproof. Contact Campbell Scientific’s technical support for more information.

-

Yes. The datalogger can control power to external devices under program control. For more information, see the “Decisions, Decisions, Decisions…” article.

To turn a generator on and off, a solid state relay with a load capacity that matches or exceeds the power of the generator is needed. The relay is controlled by one of the control ports on the datalogger.

-

Campbell Scientific dataloggers do not directly support LonWorks, but an industrial protocol converter can be used to add a datalogger to a new or existing LonWorks network. The protocol converter sits between the datalogger and the network, and it converts LonWorks requests to a protocol supported by the datalogger, such as Modbus, DNP3, SNMP, or others.

-

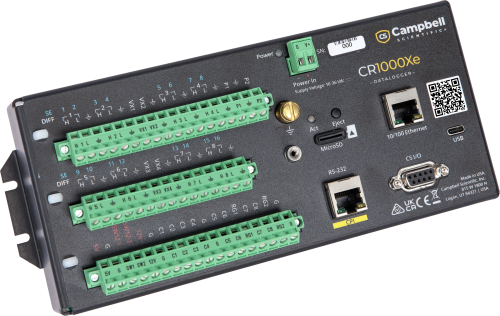

Dataloggers, which may also be referred to as Measurement and Control Units (Systems) or Microloggers, are the heart of a data acquisition system. They measure sensors at a specific scan rate, process data, store the data, and initiate telecommunication. Our dataloggers also have control capabilities allowing them to respond to specific site conditions by opening flood gates, turning fans off/on, etc.

-

Campbell Scientific dataloggers do not directly support Profibus, but an industrial protocol converter can be used to add a datalogger to a new or existing Profibus network. The protocol converter sits between the datalogger and the network, and it converts Profibus requests to a protocol supported by the datalogger, such as Modbus, DNP3, SNMP, or others.

-

Campbell Scientific dataloggers do not directly support BACnet, but an industrial protocol converter can be used to add a datalogger to a new or existing BACnet network. The protocol converter sits between the datalogger and the network, and it converts BACnet requests to a protocol supported by the datalogger, such as Modbus, DNP3, SNMP, or others.

For more information about BACnet, see the “BACnet to Modbus/Modbus to BACnet Protocol Conversion” application note.

-

Possibly. If a voltage greater than 16 Vdc is applied to the wiring panel, it could damage the input and result in inaccurate measurements.

Additionally, in some cases the sensors can be damaged if they are wired to the wrong channels. If a sensor, wired into an analog input channel, has an output of more than 5 Vdc, measurements on adjacent analog input channels may be upset. For example, the maximum full-scale range on the CR5000 is ± 5Vdc.

-

Yes. A datalogger can address up to 15 SDM addresses (0 through 14). (SDM address 15 is reserved for the SDM Group Trigger Command.) Remember that SDM is a serial communications protocol; as more devices are added to the SDM bus, it takes more program execution time to transmit the data.

-

The CR1000, CR800, CR850, and CR3000 can accept PakBus connections from multiple ports simultaneously, provided that all of the connecting nodes have unique PakBus addresses.

-

Yes. All Campbell Scientific dataloggers currently have nonvolatile memory. Nonvolatile memory was added to the CR10X in 1996. All datalogger models introduced since then have included nonvolatile memory.

Nonvolatile memory is reliant on the 3 V lithium battery inside the datalogger. As long as this internal battery has a charge above 3 V, no data should be lost if the datalogger loses power.