China is making strides in the global wind energy market, especially when it comes to manufacturing wind turbines. Companies such as Goldwind, Envision Energy, and Ming Yang are leading the charge and making their mark worldwide. As the wind energy sector keeps growing, it's becoming clearer just how crucial effective load testing and monitoring are when developing, certifying, and operating wind turbines.

In the world of wind turbine technology, load testing is vital for keeping our turbines strong, performing at their best, and lasting longer. But, performing thorough load testing out in the field comes with its share of challenges. We need monitoring systems that are tough enough to handle harsh conditions and reliable enough to give us accurate data.

Campbell Scientific’s Granite™ Volt 116 XD module has really stepped up to tackle the hurdles of wind turbine load testing in China. This module is a game changer, providing a dependable way to measure bonded foil strain gauges using the Wheatstone bridge technique. The Volt 116 has been embraced by certification bodies and wind turbine manufacturers across China, thanks to its tough build and cutting-edge capabilities.

Implementing the Volt 116 XD module for wind turbine load testing is a well-thought-out process that covers type certification and ongoing monitoring throughout the turbine's life.

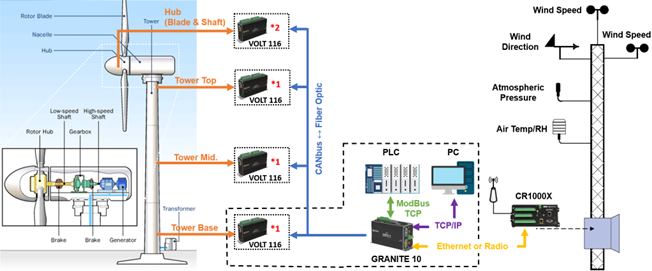

For type certification monitoring, independent certification bodies put new wind turbine models through rigorous tests to meet industry standards and regulations. They strategically place Volt modules all over the turbine, from its base to the nacelle, to measure bonded foil strain gauges. The data collected are then sent to the central Granite 10 data-acquisition system using fiber optics through the controller area network (CAN) bus, for easy analysis and integration.

After the turbine is certified, the Volt modules monitor various forces and stresses affecting the turbine's structure and components during operation. This real-time monitoring helps with fine-tuning performance, maintaining structural integrity, and extending the turbine's life.

Using the Granite Volt 116 XD module has made a big impact on wind turbine load testing and monitoring in China in the following ways:

- Enhanced Reliability: The module has proven itself to be reliable and sturdy, even in tough field conditions.

- Cost Savings and Efficiency: By being durable and packed with advanced features, the module has helped cut costs and reduce integrated system size.

- Improved Data Transmission: With CANbus data streaming, the Volt 116 makes it easy to integrate with existing monitoring systems, improving data transmission capabilities.

- Technique Advancements: Successfully implementing the Granite VWire 305 has shown the feasibility of using a dynamic vibrating wire (VW) technique for surface strain measurements on concrete in hybrid wind tower designs.

This case study emphasizes how crucial it is to have effective load testing and monitoring when developing, certifying, and operating wind turbines. Campbell Scientific Granite Volt 116 XD and VWire 305 modules have been game changers in tackling the challenges of wind turbine load testing in China. These modules provided reliable solutions for monitoring the structural health and optimizing the performance of these turbines.

As China keeps growing its footprint in the wind energy sector, advancements in load testing and monitoring technologies will continue to be key drivers of innovation and sustainability in wind turbine operations.