This product is no longer available and has been replaced by: CR1000. Some accessories, replacement parts, or services may still be available.

| Services Available | |

|---|---|

| Repair | No |

| Calibration | Yes |

| Free Support | No |

Overview

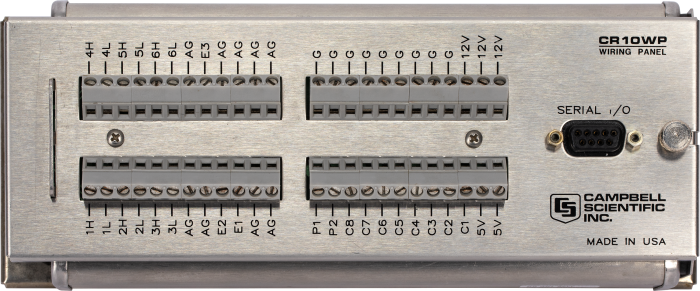

The CR10 was a predecessor of the CR10X. The CR10X was eventually replaced with the CR1000. The CR10 consisted of a CR10M Measurement and Control Module and a CR10WP Wiring Panel.

Read MoreBenefits and Features

- Manufactured from 1987-1996

- Array-based data format

- Repairs still available

Images

Technical Description

The CR10 had 12 single-ended (six differential) analog input channels, three switched excitation outputs, eight input/output control ports, two pulse counting channels, and a serial I/O port. It provided sensor measurement, timekeeping, data reduction, data/program storage and control functions. Up to 29,908 data points were stored in it's internal memory.

CR10s manufactured after 1 December 1993 (SN>19273) contained an internal jumper that supported use of 2 or 4 kbytes program memory (appropriate PROM also required).

Specifications

- 12 single-ended (six differential) analog input channels

- Three switched excitation outputs

- Eight input/output control ports

- Two pulse counting channels

- One serial I/O port

- Stored up to 29,908 data points in internal memory

Compatibility

A typical field-based CR10 system consisted of:

- CR10 with OS10 Operating System

- Alkaline or Rechargeable Power Supply

- Weatherproof Enclosure (CR10s ordered with an environmental enclosure were mounted on the enclosure backplate at the factory)

CR10 peripherals such as the CR10KD and CR10TCR, as well as sensors and data retrieval peripherals, were added to complete the system.

Related Documents

Product Brochures

Manuals

Related FAQs

Number of FAQs related to CR10: 2

-

The CPU of the datalogger can be removed and mated with a different CR800 wiring panel. This can be done by removing the four corner nuts on the underside of the CR800. Do not loosen the two middle nuts. Be careful not to damage the pins mating the CPU with the wiring panel.

-

The information included on a calibration sheet differs with each sensor. For some sensors, the sheet contains coefficients necessary to program a datalogger. For other sensors, the calibration sheet is a pass/fail report.

Case Studies

Nearly 60 monitoring stations record water level and quality parameters at reservoirs, canals, pipelines, and......read more

More than 50 CR10-based monitoring systems were used for structural monitoring during the construction of......read more

The Mogao Grottoes consist of 492 caves carved into a cliffside near Dunhuang, China. The......read more

The Poulsbo Marine Science Center is a non-profit educational facility located on Liberty Bay on......read more

Following an inspection a decade ago, the Welsh Office was advised to reduce the allowable......read more

Controlling the water level of the Neuquen, Limay, and Negro rivers of Argentina is a......read more

To overcome the difficulties associated with monitoring the hydrophysical properties of water in deep wells,......read more

Twenty houses in Dade County, Florida were instrumented with data loggers and sensors by the......read more