Calibration Essentials: Importance

by Michael Jacobs | Updated: 03/04/2024 | Comments: 1

In the world of measurement and data acquisition, ensuring instrument accuracy is paramount. Regular calibration is essential to maintaining the integrity of your measurements and safeguarding your operations. But what exactly is calibration, and why is it so important?

In this three-part blog series, we’ll explore the importance of calibration and provide you with a guide on the level of traceability assurance to use and how frequently to calibrate your instruments.

Defining Calibration

Strictly speaking, calibration refers to the comparison of the measurement result by a device being tested to those of a reference measurement standard. This process assesses the device's ability to accurately measure its intended parameter and identify any discrepancies that may affect its performance. Calibration is not to be confused with adjustment, which involves correcting or modifying the device to align with the reference standard.

Assessing Risks and Data Validation

Calibration is crucial for ensuring measurement device reliability and data integrity, particularly in situations where inaccurate measurements could pose safety hazards or financial implications. To determine the need for calibration, consider the following factors:

A. Risk Mitigation

- Safety: If the device monitors conditions that impact personnel safety, calibration is essential to prevent accidents and ensure their well-being.

- Property Protection: If the device monitors activities that could lead to equipment or property damage, calibration is crucial to prevent costly breakdowns or losses.

B. Data Validation

- Scientific Research: In scientific research, where data are subject to scrutiny, calibration ensures the reliability of experiments and the validity of findings.

- Financial Impacts: In quantitative analysis with financial implications, calibration guarantees the accuracy of data used for decision-making and financial forecasting.

C. Operations Impact

- Product Quality: Calibration is critical for maintaining the integrity of research and development (R&D), manufacturing, or production processes, ensuring the quality of products sold to consumers.

- Regulatory Compliance: If your industry adheres to regulations or industry standards such as ISO, IEC, ANSI, or WMO, calibration is mandatory to maintain compliance and avoid regulatory sanctions.

Establishing Calibration Intervals

Calibration frequency isn't a one-size-fits-all issue. It's a carefully orchestrated interaction between the environment your device occupies, its wear and tear, and the potential consequences of inaccurate measurements. Users need to find the best spot that minimizes the risk of questionable data impacting their operations.

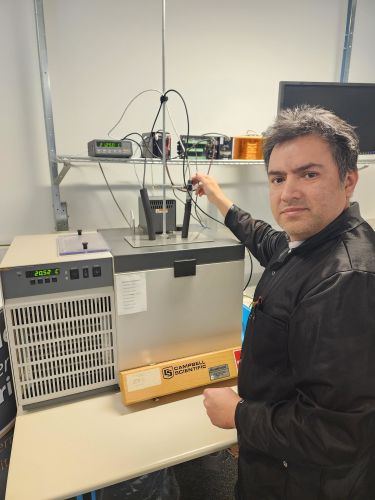

That's where Campbell Scientific comes in, your trusted partner in keeping your equipment in its best condition. Our factory-trained and certified technicians understand the latest equipment and procedures to offer a comprehensive suite of calibration, repair, and maintenance services. Whether you need scheduled calibrations to fulfill manufacturer recommendations, on-site visits to minimize downtime, or preventive maintenance programs to extend your equipment's life, we have the expertise and resources to meet your needs.

Remember, regular calibration isn't just a checklist item to perform; it's an essential safeguard for accuracy and reliability, especially for devices in safety-critical applications, involving data-driven decisions, or where regulations demand precise measurements. By identifying which instruments need calibration and setting appropriate intervals, you minimize risks, maintain data quality, and build trust in your measurement processes. Consider it the harmony that strengthens your data's symphony!

A Final Word

I hope this article has helped illustrate the importance of calibration for your measurements and the accuracy of the data you depend on. In the next blog article in this series, we’ll take a closer look at the importance of traceability assurance and its different levels. If you have any questions or comments, please post them below.

Credits: Ramatoulaye Nabi of Campbell Scientific contributed to this article.

Michael Jacobs is the Manager of Calibration and Repair Services at Campbell Scientific, Inc. With expertise in DC/low-frequency measurements, he analyzes measurement uncertainty and quality standards such as ISO 9001, ISO 17025, ANSI Z540, and relevant JCGM documents. Michael was trained in the US Air Force Precision Measurement Equipment Laboratory AFMETCAL program and has more than 30 years’ experience in measurement science.

Michael Jacobs is the Manager of Calibration and Repair Services at Campbell Scientific, Inc. With expertise in DC/low-frequency measurements, he analyzes measurement uncertainty and quality standards such as ISO 9001, ISO 17025, ANSI Z540, and relevant JCGM documents. Michael was trained in the US Air Force Precision Measurement Equipment Laboratory AFMETCAL program and has more than 30 years’ experience in measurement science.

Comments

Saadi Al-Musawi | 03/05/2024 at 03:40 AM

Dear Michael

Thank you.

Kindly what are the calibration instruments that we can recommend to customers for labrotary calibration for sensors and data verification.

Thank you.

Dr. Saadi Al-Musawi (CSI partner)

Please log in or register to comment.